Polybase GT

Polytan PolyBase GT, the next step for the perfect elastic layer: Polytan’s latest Green Technology development combines the well-known benefits of in-situ elastic layers with the environmental benefits of a recycled product and a revolutionary new technology for climate-friendly carbon dioxide utilisation. This will further improve the already excellent environmental performance of our elastic layers.

All the familiar benefits of our Polytan elastic layers remain fully intact and make the new PolyBase GT the ideal basis for synthetic turf systems, which should perform at their best in terms of both sporting performance and sustainability.

BINDER WITH REVOLUTIONARY CO2

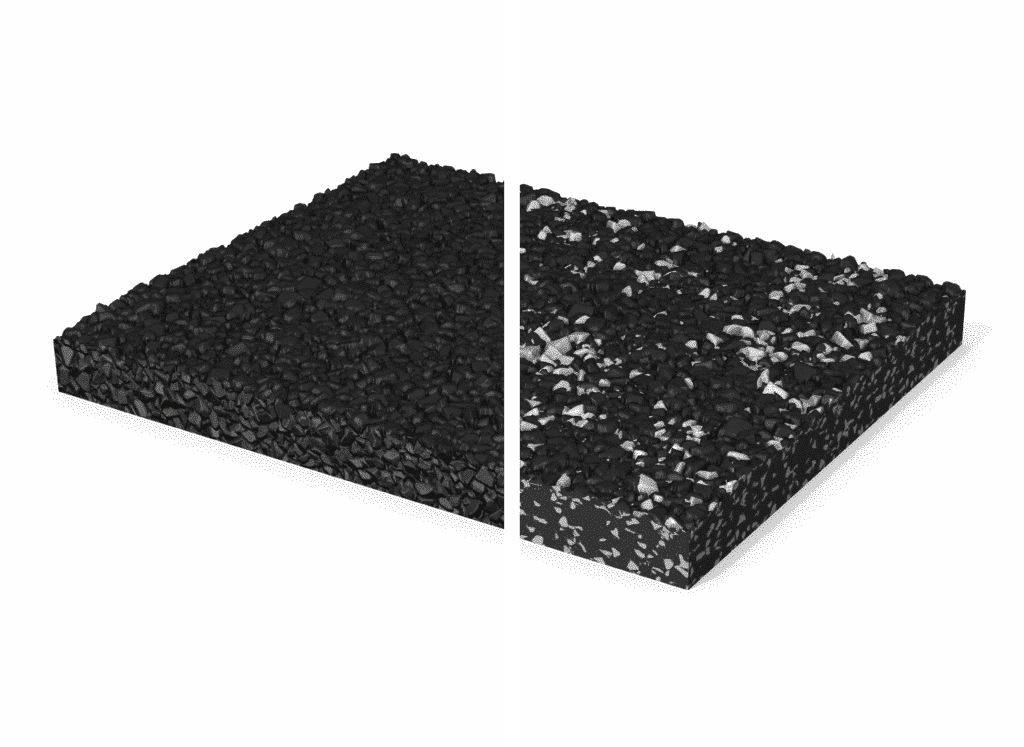

MATERIAL

RUBBER GRANULES MADE FROM 100 % RECYCLED MATERIAL

LONG-LASTING ELASTICITY

Sporting features of our elastic layers are in particular the elasticity values which permanently ensure the safety of the players: even with an extreme displacement of the infill materials or a completely worn grass surface, the shock absorption and deformation are optimally preserved.

OPTIMAL DRAINAGE AND ENVIRONMENTAL PROPERTIES

The elastic layer not only ensures sports functionality, but also has consistently reliable drainage properties. The water permeability of the system also contributes to the prevention of surface sealing. In addition, the environmental compatibility of the elastic layer is monitored by complete quality control according to the strict guidelines for soil and water.

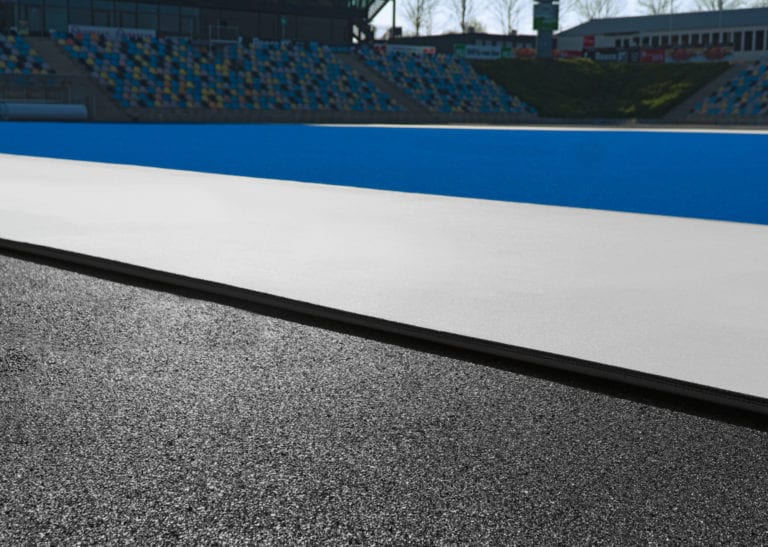

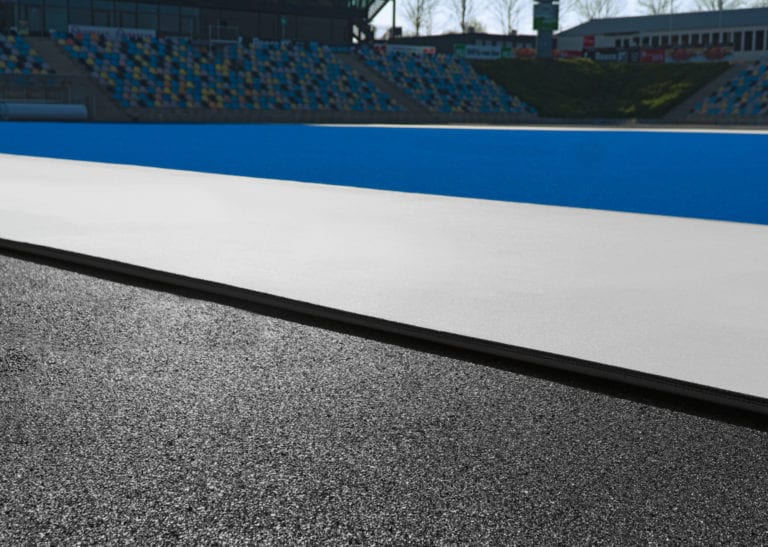

PERFECTLY LEVEL AND SEAMLESS – THANKS TO IN-SITU CONSTRUCTION

The in-situ construction of the polytan elastic layers ensures that a perfectly flat surface with defined angles of inclination is created. This construction method is also the only way to create a seamless connection between the laid tracks that are always required for a sports field. This prevents unevenness and the formation of cracks, while also ensuring that the turf surface laid on top does not develop ripples and gaps.